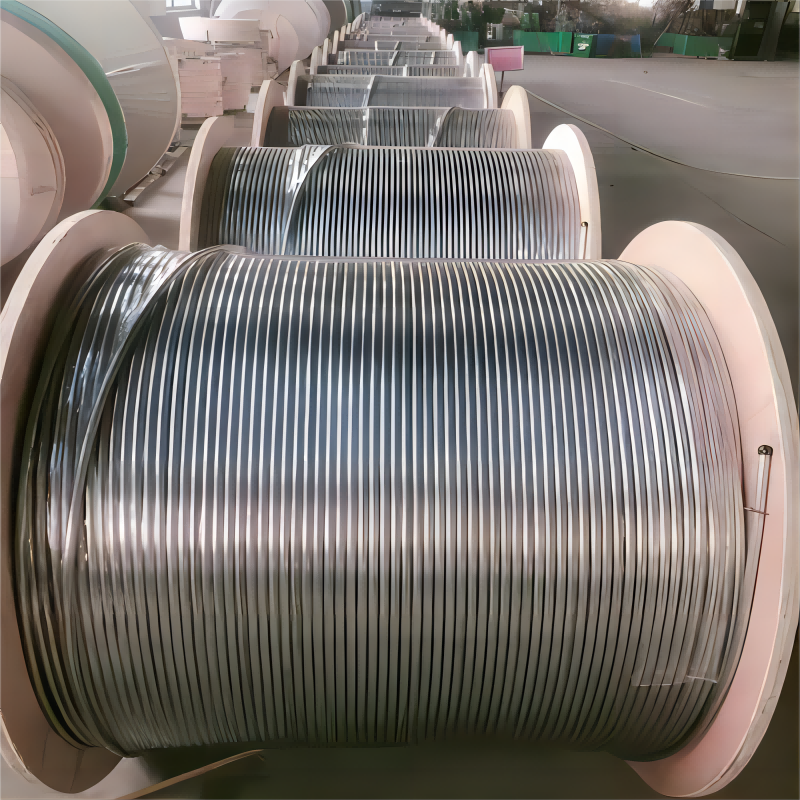

| Deskrizzjoni | Tubi tal-Kolja ta 'l-Azzar li ma jsaddadx mingħajr saldatura | ||

| Materjal u Standard u Daqs | Materjal: 201,202,301,304,304L,310S,316,316L,321,347 Standard: ASTM (ASME) SA / A312 / A213 / A269, DIN, JIS, EN | ||

| Dijametru 'l barra: Φ6mm-25mm Ħxuna tal-ħajt: Φ0.7mm-2.11mm Tolleranza: OD: ± 0.08mm, WT: ± 10% | |||

| Tul | Skont daqsijiet differenti, it-tul tal-coil wieħed huwa fi ħdan 500 metru, it-tubu tal-coil kollu mhuwiex punt iwweldjat | ||

| Trattament tal-wiċċ | Pickling Jew Pollakk Ittemprat | ||

| Tekniku | Irrumblar kiesaħ l-ewwel, imbagħad coil miġbud fil-kesħa | ||

| Tip ta' Kunsinna | Artab | ||

| Tip | Seamless u Welde | ||

| Applikazzjoni | It-tubi tal-coil tal-azzar li ma jsaddadx jintużaw ħafna fit-Tħaffir taż-Żejt, il-Kimika, l-Industrija tal-Manifattura tal-Vapuri tal-Fwar, l-Iskambju tas-Sħana u l-Industrija Kimika tal-Kondensatur tat-Tkessiħ, il-Pipeline tal-Gass eċċ | ||

Stainless Steel Grad

| Kompożizzjoni Kimika | Kompożizzjoni tal-Materjal | 201 | 304L | 304 | 316 | 316L |

| C | ≤0.15 | ≤0.03 | ≤0.08 | ≤0.08 | ≤0.03 | |

| Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

| Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤2.00 | |

| P | ≤0.06 | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.035 | |

| S | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Cr | 16-18 | 18-20 | 18-20 | 16-18 | 16-18 | |

| Ni | 3.5-5.5 | 8-12 | 8-10.5 | 10-14 | 10-14 | |

| Mo | 2.0-3.0 | 2.0-3.0 | ||||

| Proprjetà Mekkanika | Oġġett Materjal | 201 | 304L | 304 | 316 | |

| Saħħa tat-tensjoni | ≥535 | ≥520 | ≥520 | ≥520 | ||

| Qawwa tar-Rendiment | ≥245 | ≥205 | ≥205 | ≥205 | ||

| Estensjoni | ≥30% | ≥40% | ≥35% | ≥35% | ||

| Ebusija (HV) | <253 | <200 | <200 | <200 | ||

Ħin tal-post: Jan-20-2023